Hill top swimming pool shell construction begins

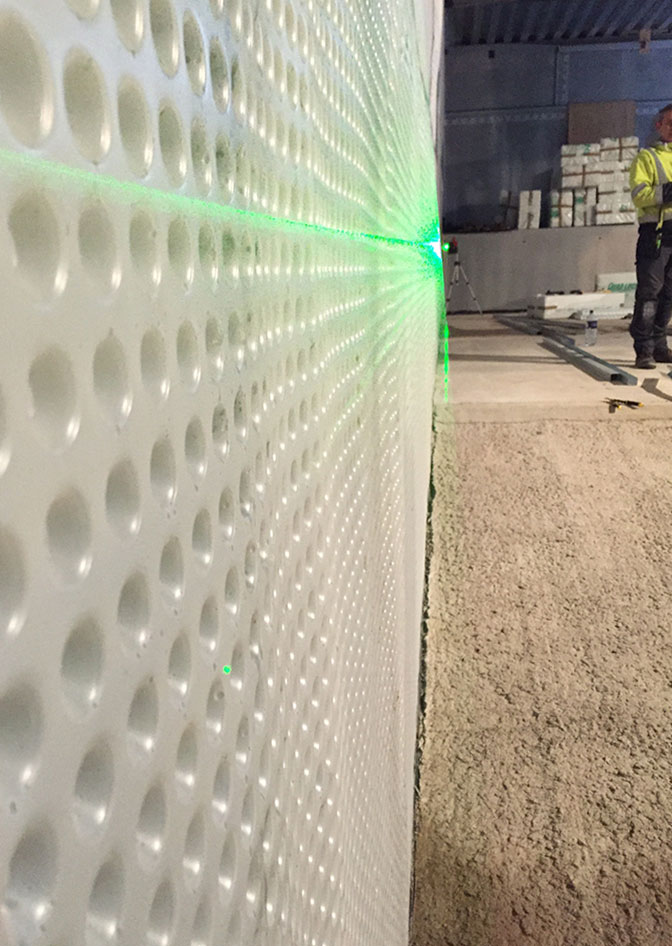

The beauty of using Quadlock ICF for swimming pool shell construction is it’s very easy to get to site no matter how difficult the location. On-top of a rather large hill, on a slab constructed by groundwork’s team a week earlier, the basic pool shell flies up within a matter of days.

Hill top swimming pool shell construction begins Read More »