Pool wall construction begins in London basement pool

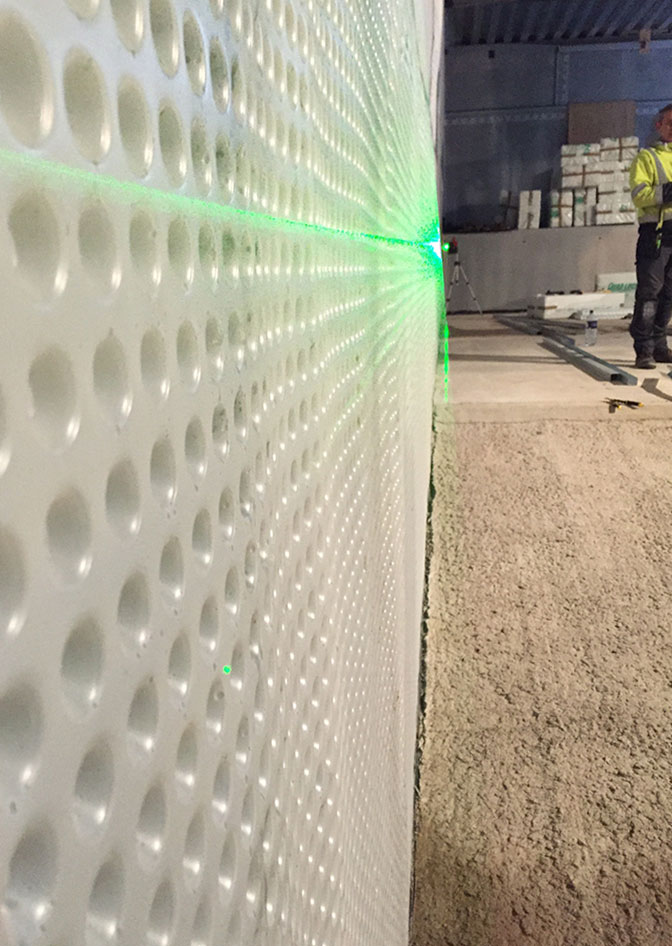

Work begins for the pool wall construction on a twin depth basement swimming pool in London. The walls are being constructed using the Quadlock Insulated Concrete Form-work (ICF) system and is being built on a reinforced slab installed by the existing site workers from Brookforge drawings. The shallow water depth is 1.3m going down to […]

Pool wall construction begins in London basement pool Read More »